Why purchase a waste oil burner:

Considerable waste oil is generated from the crankcases of millions of automobiles and trucks whenever the oil is changed. The disposal of the vast quantities of discarded waste oil constitutes a great problem, and many people choose to illegally dump oil rather than pay to have it properly disposed.

As gas and oil prices continually skyrocket, many people are finding it hard to comfortably heat their homes without breaking their budget. Many larger shops are struggling to stay afloat, as the cost of heating their shops increasing becomes one of their larger expenses. And most people are questioninghow much longer can we last like this? How much longer can we keep depleting our non-renewable resources while increasing our waste?

A waste oil burner solves both these problemsusing a resource that is already abundant (discarded oil) to perform a task that normally costs a lot of money (heating a building)

When properly performed, efficient and complete incineration of waste oil is simple and provides many benefits, and results in immediate savings. In most cases, the cost of waste oil heating equipment is returned in one to three years. With a KingBuilt.com waste oil combustion system, the cost of preheating and maintenance is minimized even further, and the savings are greater and the return on investment faster!

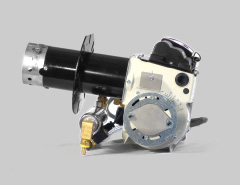

How a waste oil burner works

Four process elements are needed for the combustion of heavier virgin heating and spent lubricating oils:

First, and most importantly, because heavier oil fuels are too thick to atomize and spray at ambient temperature, they must be preheated. The heated oil becomes reduced in viscosity enabling it to be finely atomized.

Second, is the atomizing of heated oil. Atomization is accomplished by spraying heated oil out of a nozzle. An aeration process involving an air atomizing nozzle and compressed air is one method. The air atomizing nozzle mixes oil and compressed air resulting in a conical fine spray of atomized oil ejecting away from the nozzle. Typically only 10-15 pounds per square inch of air pressure along with 1-10 pounds per square inch of oil pressure is all that is needed.

Third, is igniting the atomized oil. This process ignites the spray and creates the combustion flame that incinerates the atomized oil. The ignition process is typically performed by an igniter that has a pair of electrodes, which emit an electrical arc across in close proximity to the atomized spray.

Fourth, is controlling all of the processes needed for combustion. It is important that the combustion process be performed in a way that is precisely controlled with safety components and features to assure a safe, reliable and thorough incineration of oil. The control system empowers and manages all the mechanical and electro-mechanical devices needed to control all the process elements mentioned above.

The problem with the Electric Heater Preheat System

Ryan Bechard, the owner of KingBuilt.com, came across a problem that was evident with all waste oil burners on the marketwhich was their method to preheat oil. Every waste oil burner on the market used high wattage electrical heating elements to preheat oil, which required an outside source of electrical energy. These elements heat a device that the oil flows through just prior to reaching a nozzle. The oil is heated by electrical elements in direct contact with the oil.

This method of preheating oil uses high wattage electrical heating elements. This requires an outside source of energy that consumes a significant amount of electricity. Customers lose a percentage of their oil energy savings due to their high electrical consumption.

Another disadvantage to this method of preheating oil is that the electrical preheat elements are slow to react. It produces temperature fluctuations of the oil's temperature in the preheat process. These temperature swings mandate frequent maintenance and create many problems within a combustion system. Oil is vulnerable to overheating at the high peak of an electrical element's temperature swing. Over-heated oil produces carbon crystals within the preheat device, causing coagulation and clogging of the oil passageway and nozzle, resulting in equipment failure. Oil is vulnerable to carbonization at temperatures as low as 90 degrees centigrade. The surface temperature of an energized electric element can reach several hundred degrees centigrade.

Over time, the overheating of the oil causes the oil to carbonize inside the preheat device, creating many problems in the combustion process. The carbon crystals created by overheated oil will plug the nozzle, causing equipment failure. The coagulation of carbonized oil inside the passageways of the preheat device restricts the oil flow causing inconsistent combustion and eventual equipment failure. Carbon build up inside the oil channels insulates the oil from the heat source.

Thermostatically controlled preheat devices heat up very slowly, typically 5 to 15 minutes. Because they heat up slowly, the oil must be kept inside the preheat device in between burn cycles in order to be prepared for the next burn cycle. The time between burn cycles is when the majority of carbonization forms due to the constant overheating of the dormant oil inside the device.

Gradual carbon coagulation on the inner surface of the heat transfer boundaries forces the electric elements to remain on longer, further increasing carbon build up. Eventually, the preheat device must be removed from the heating appliance, disassembled, cleaned out, reassembled and reinstalled back onto the heating appliance. With thermostatically controlled preheat systems, an operator is typically required to send the combustion system back to the manufacture or qualified manufacture's distributor to have the overhauling process performed. Overhauling costs an owner a significant amount of time and money to keep the system operable.

At the low end of the thermostatically controlled electrical element's temperature swing, the quality of oil atomization decreases. This often happens before the thermostat turns on the electric heating elements because the thermostat is slow to react to the oil temperature. When oil cools, it thickens, thus reducing the quality of oil atomization as the oil droplet size increases. These larger droplets, if not completely incinerated, will project past the flame where they can accumulate and build up unburned fuel inside the furnace or boiler. This unburned oil fuel accumulation can propose a serious hazard to the end user.

The high temperatures of the thermostatically controlled electrical elements poses another hazard. Because of high element temperatures, our competitors' preheat systems must implement vast safety systems to prevent a fire. Prior art's control system is extremely complex with sensors, switches, wiring and controllers to prevent a hazardous condition.

In summary, using thermostatically controlled electrical elements to preheat oil is inefficient, undependable, potentially hazardous and is expensive to maintain.

The KingBuilt Solution - Hydronic Preheat System

KingBuilt.com has a patented hydronic preheat system for their burners. This transfers heat energy from a heated liquid (water) to the oil just prior to being incinerated. When installed on a boiler, it is able to utilize the heat energy created by the combustion process itself versus consuming electricity to create heat energy for preheating.

With our Hydronic Preheat system, heat energy is exchanged from running hot water through the device to the oil. The oil is brought to and maintained at an optimal atomization temperature with minuet temperature fluctuations prior to combustion. With this method, oil cannot reach a temperature any hotter than the liquid with which it is being heated. With this method of preheating, carbon creation is eliminated because preheat temperature fluctuations are vastly minimized. Whereas oil is vulnerable to carbonization from direct overheating, water is not. Using water to convey heat energy to oil for preheating removes the risk of overheating and carbonizing oil. The water acts as a buffer that absorbs temperature extremes and fluctuations between the heat source and oil.

We use water that is maintained at approximately 80°C (176°F) to preheat oil, minimizing temperature fluctuation. Since the oil's temperature can't exceed the heated liquid's temperature, carbon creation and the removal thereof does not need to be performed. This significant advantage makes this invention much more attractive to the end user.

With a hydronically controlled preheat system; the oil is heated rapidly, typically within 15 to 30 seconds, and is heated just prior to a burn cycle. Because of the high speed of heat conduction from the heated liquid to oil, this invention does not need to keep the dormant oil inside the preheat device heated in between burn cycles. Also, electrical energy consumption needed to keep the dormant oil heated between burn cycles is eliminated.

Using a heated liquid to preheat oil is extremely safe. No fire hazard is caused by circulating water between the heated water source and the oil. The control system simply energizes a pump to circulate a heated liquid. There are only a few components involved with this preheat invention.

A significant advantage of the hydronic preheat system is having the option of capturing and utilizing heat energy from the combustion process to preheat oil rather than consuming electricity to create heat energy for preheating. The method of using water does not overheat oil, eliminating the many problems caused by carbonized oil creation and large preheat temperature fluctuations as found in electric heaters. Therefore, the cost of incinerating multiple oil fuels is significantly less.

The multi oil heating market has long sought a reliable and cost effective means of incinerating heavier oil fuels for heating purposes and waste oil elimination. Many oils such as spent lubricating oil, industrial heating oil and cooking oils burn very efficiently when appropriately preheated and incinerated within a combustion system. In an age demanding higher efficiencies with regard to energy usage, the KingBuilt Boiler and Furnace systems provide a much more efficient method of incinerating both heavy virgin and used oil fuels.